In order to contribute to the validation of these tests, whose reliability has been the subject of discussions, quality control is a fundamental ally.

In the current pandemic scenario, the contribution and credibility of laboratory tests for Covid-19 has been widely reported. To increase the reliability of these reports, Controllab has just launched the Proficiency Test for SARS-CoV2 (Covid-19).

The importance of laboratory tests for health care is widely known. Therefore, analytical systems support the confidence that clinical staff must have in the results received.

The Proficiency Test (also known as External Control) monitors process trends (inaccuracy), commonly related to linearity, specificity, sensitivity, interference and calibration characteristics. These variables are inherent to the analysis process and keeping them under control is essential so as not to compromise the quality of the laboratory reports.

Having quality control to guarantee the reliability of laboratory tests, and of national origin, to avoid the logistical impacts caused by the pandemic, collaborates to strengthen the Brazilian health system.

The Proficiency Test follows the criteria of ABNT NBR ISO/IEC 17043 and Controllab is accredited by the General Accreditation Coordination (Cgcre / Inmetro), under the number PEP 0003, according to the scope published in Inmetro.

Laboratory quality control programs of Controllab help the laboratory obtain recognition from physicians and patients regarding the quality of the reports issued.

Controls available for SARS-CoV2 (Covid-19)

The first round of the Proficiency Test (EP) for SARS-CoV2 of Controllab was held in May and helped laboratories evaluate the analytical performance of their systems. The behavior obtained in the interlaboratory comparison was analyzed by a group of specialists in the diagnostic sector and made available in a report. The content is enriched with information to assist manufacturers of diagnostic kits and, especially, laboratories, demonstrating the relevance of quality control in periods of uncertainty and complexity. Access the document.

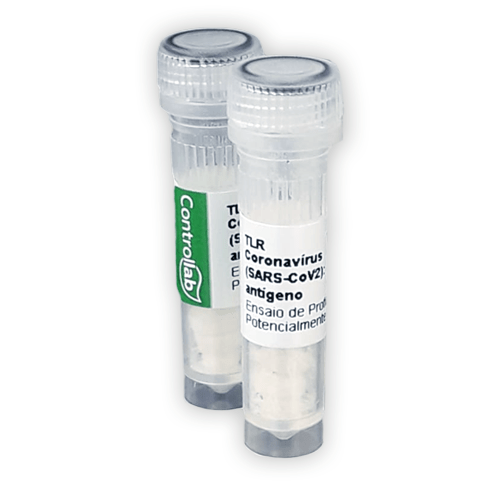

Controllab offers internal quality control (CQI) for all SARS-CoV2 detection methodologies. The programs of the CQI of Controllab are considered third-party controls. The materials have interlaboratory valuation in different remote laboratory test systems (TLR), molecular and automated tests, such as: Roche Elecsys (Cobas e601, e602, e411, e801), Abbott (Architect i1000sr and i2000sr), Euroimmun, MagLumi, among others . These multiple valuations allow the laboratory to detect more sensitive variations, which are not perceived in the controls of the manufacturers of the analytical system.

The controls are lyophilized – allowing better stability during transportation – and distributed in different compositions to meet the most varied routines. These controls are available for immediate dispatch, upon request from the laboratory, or scheduled monthly.

Molecular Testing RT-PCR

-

CL

RDT Immunology Coronavirus (SARS-CoV2)

Coronavirus (SARS-CoV2)1 IgG Coronavirus IgM Coronavirus Total Coronavirus immunology RDT by immunochromatography and immunofluorescence methods. Related tests 1Covid ¹Rapid Diagnostic Test Covid ¹Rapid Test Covid

-

CL

RDT Coronavirus (SARS-CoV2) – Antigen

RDT Coronavirus (SARS-CoV2)1 – Antigen Related tests 1Covid ¹Rapid Diagnostic Test – Covid ¹Covid Rapid Test

-

CL

Coronavirus (SARS-CoV2) – Immunology

IgG IgM IgA Total IgM/IgA IgG Avidity Immunology Automation by enzyme immunoassay, chemiluminescence, electrochemiluminescence, microparticles by chemiluminescence. Related tests Covid

-

CL

Coronavirus (SARS-CoV2) – Molecular Biology

Coronavirus (SARS-CoV2) – Molecular Biology Detection of SARS-CoV2¹ genes and identification of attention/concern variants by Real Time RT-PCR techniques. Coronavirus (SARS-CoV2) – Molecular Biology: Saliva Detection […]

In addition to the new coronavirus, it is necessary to keep chronic diseases under control, in order not to be aggravated with Covid-19 (disease caused by the virus). The patient with Covid-19 also needs other complementary exams (such as a complete blood count, D-dimer, PCR and others) to monitor and contain the evolution of the disease. To optimize resources, it is also essential to monitor the routine of tests for differential diagnosis of respiratory diseases for coronavirus.

Due to team adjustments and other laboratory routines affected by the pandemic, maintaining quality control in all tests performed by the laboratory is essential to avoid errors in the laboratory analytical phase and repetition costs.